11KW Rubber Injection Moulding Machine / Fast Speed Silicone Baby Bottle Making Machine

Contact Person : Angelina

Phone Number : 15918448424

WhatsApp : +8615918448424

| Minimum Order Quantity : | 1 SET | Price : | USD43,000~USD50,000 |

|---|---|---|---|

| Packaging Details : | Wooden case | Delivery Time : | 30 working days |

| Payment Terms : | L/C, D/A, D/P, T/T, Western Union | Supply Ability : | 10 SETS per month |

| Place of Origin: | China | Brand Name: | TYM |

|---|---|---|---|

| Certification: | ISO, CE | Model Number: | W4545 |

|

Detail Information |

|||

| Shot Volume: | 148g | Clamping Force: | 130T |

|---|---|---|---|

| Tie-Bars Space: | 450*450mm | Ejection Force: | 1.3T |

| Machine Weight: | 5.2T | Motor Power: | 12.1KW |

| Machine Dimension: | 4000*1200*1900mm | ||

| High Light: | 1.3T Injection Moulding Machine,12.1KW Hydraulic Injection Moulding Machine |

||

Product Description

Hydraulic High Speed Injection Molding Machine For Baby Products

How to improve the production quality and efficiency of liquid silicone nipple mold.

1. Point to point cold runner

According to the size of the liquid silicone nipple, the liquid silicone nipple mold generally has one out of four points, one out of six points, one out of eight points, one out of sixteen points, each point adopts a one-to-one cold runner way to enter the rubber.

2. Rubber inlet

Liquid silicone nipple mold can achieve zero water inlet, but in the production of standard mouth and wide mouth nipple, in order to increase the production efficiency and product quality, the rubber inlet is generally 5mm long, one is to shorten the curing time of liquid silicone nipple, the other is to facilitate the consistency of subsequent punching positions.

3. No flash

The liquid silicone nipple mold adds a vacuum pumping system, and actively vacuumizes and exhausts air, so as to realize the production of liquid silicone nipple products without flash and reduce the manual work of secondary tearing.

4. Automatic demoulding

The liquid silicone nipple mould is designed to have no excess nozzle, overflow glue and flash residue. The air blowing and mechanical arm are used for automatic demoulding.

![]()

The main feature of the horizontal Liquid Injection Molding Machine :

1,Direct pressure injection barrel-high precision,portable, easy to change and clean.

2,1:1 quantitative cylinder, The output ratio error of glue A and B is within 1%.

3,Static+dynamic mixer to mix the material and color more thoroughly.

4,Digital control slurry pump,accuracy up to 0.01g

5,The servo system-is 12.1KW, energy-saving 60%

![]()

![]()

TYM factory:

![]()

![]()

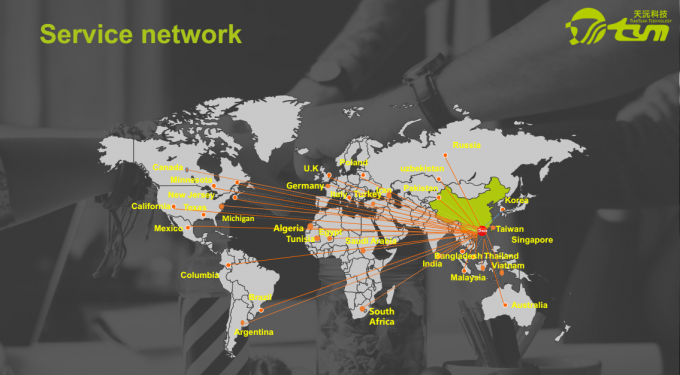

Our service:

Pre-sale service

According to the customer’s investment budget, plant planning and other forms of pre-sales services to ensure customer's planning is reasonable, standardized and cost-saving, will provide matched mold and select suitable machine according to customer’s requirement.

On-purchase service

Enable to be familiar with the operation and maintenance of the TYM's machine.

1) Installation of LSR machine and new machine debugging service.

2) Machine operator training.

3) Training of technicians.

After-sales service

1) Free training for the operation and maintenance independently.

2) Help to solve and reply technical problem and question timely, TYM will arrange professional engineer for the instruction and will provide the technical guidance for free.

3) TYM will give priority to customer when the system on the LSR machine need to be upgraded.

Enter Your Message